Down

hill

200

time matters

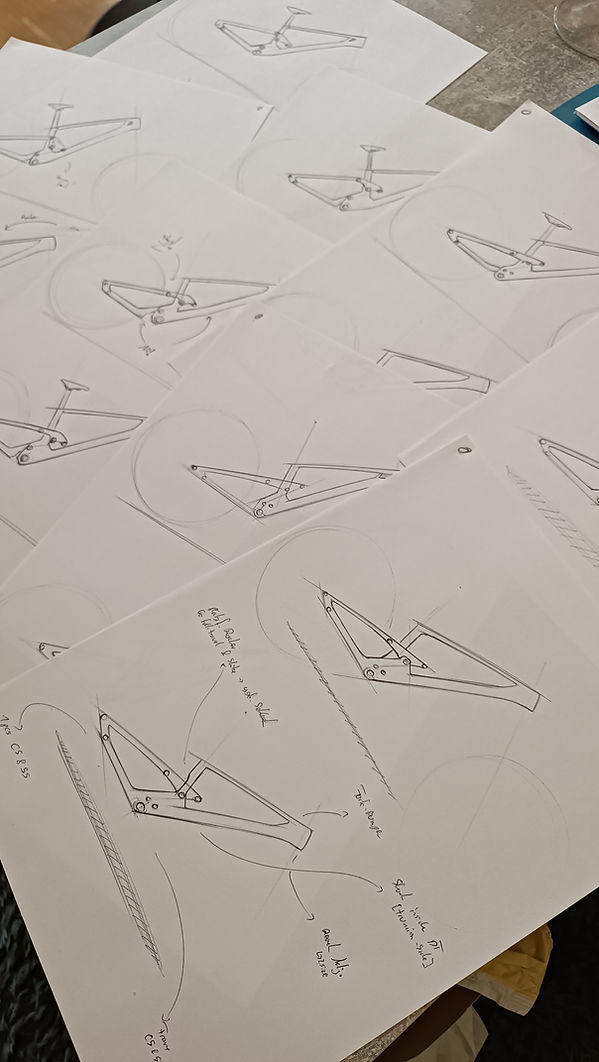

The Downhill Bike is the peak of full suspension bicycles. The Formula 1 of offroad cycling. Therefor the expectations as well as demands are very high and very specific. Basically, the only purpose is to go fast. But there are also factors like handling, predictability and efficiency that are important and lead to fast times.

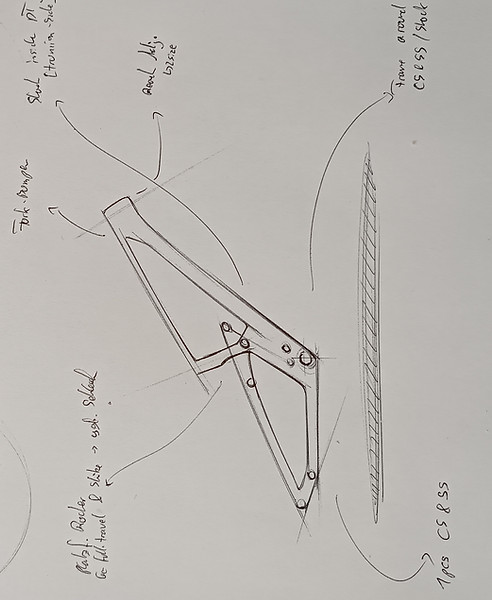

So, I developed a completely new suspension kinematic with 200mm of travel. It is a 4-bar layout with Horstlink. Thanks to that I could tweak the suspension curves very precisely where I wanted them to be and still place the pivots in a way, I could implement my design as well. With growing demand of pedaling efficiency, also in downhill sport, anti-squat values rose over the past generations of Downhill Bikes. In my case there is just over 130% of it at 35% SAG. The same goes with anti-rise. Here I managed to squeeze out 52.5% at SAG. Overall, there is 22% of progression in the leverage ratio with just a little bit of regression at the very beginning of the curve.

For more stiffness in the rear end and more predictability that comes with that, I decided to bolt the chainstays and Rocker inside the frame, rather than outside which is common. That also helps for a very sleek design.

In the first design proposals, I went for the rather uncommon way of turning the shock with the dials to the top for better accessibility. That would have helped with clearance inside the downtube when the shock moves through its travel. As every shock has it’s dials in a different position that idea proves to be difficult to convert into reality. To ensure the clearance for the biggy-back now, the downtube protector ensures for more space down there.

Another change from the initial design is the seattube-area. Instead of the custom seatpost design with its two arms that are mounted inside the Frame, there is a classic, round seatpost now. In favour of the design and the clearance of the rather big rocker, I didn’t change the resulting, very short seatpost insertation of the frame. In reality, if that design would go into production, that would be a problem, as the angle of the seattube is also very flat.